At AboutMechanics, we're committed to delivering accurate, trustworthy information. Our expert-authored content is rigorously fact-checked and sourced from credible authorities. Discover how we uphold the highest standards in providing you with reliable knowledge.

What is Furnace Annealing?

Furnace annealing is a heating and cooling method frequently used on metal, glass, ceramics, and silicon wafers. It generally improves qualities in the various materials — such as durability in glass and ceramics, ductility and strength in metals, and electrical conductivity in silicon wafers. This helps develop the machinability of the different materials. As its name implies, this process typically takes place inside an oven, known as an annealing furnace. This is generally done so that the temperature can be controlled during heating and cooling.

One of the products that furnace annealing is typically used in making is metal wire. This practice changes the internal structure of many metals, like steel, copper, and silver, among others, so that their ductility, or ability to stretch, is enhanced. This happens because the different metals are heated to just beyond the temperature at which the metals will recrystallize, meaning that the atoms in the metals move to a state of equilibrium. When metals do this, they are usually healed of any stresses that existed in them, which would cause them to break, as opposed to being stretched.

Sometimes, when metal is being put thorough this process, a bright annealing furnace is used. It typically uses either a special mix of gases, which reduce the presence of oxygen, carbon, or nitrogen that the metal is exposed to, or it can anneal metals in a vacuum. The furnace is then referred to, more specifically, as a vacuum annealing furnace. With either method, the end product maintains its luster.

The temperature for furnace annealing is dependent on the kind of material being treated. Each metal has a different critical temperature at which it will recrystallize. Similarly, glass and ceramics have differing temperatures at which their atoms move to their most stable configuration. In addition, each substance has a different time and temperature to which it should be cooled for annealing to be complete. For instance, the high temperature just above silver recrystallization is 1,778°F (970°C). It should then be cooled to 932°F (500°C) for several hours before it is fully annealed.

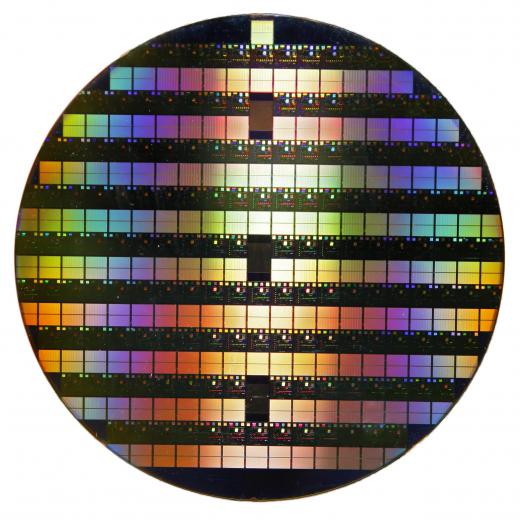

When furnace annealing is used to process silicon wafers for manufacture of semiconductors, a batch annealing furnace is often utilized. In this manner many silicon wafers can be annealed at once. Since this can take several hours, using a furnace capable of handling many pieces at once can be economical and time-saving.

AS FEATURED ON:

AS FEATURED ON:

Discussion Comments

An advanced form of annealing is part of the process used to make ceramic body armor at the company where I work. The plates have to be shaped very precisely, and hard enough to stop bullets. The temperatures in the manufacturing process can get very high, and they have to be controlled very precisely.

The factory is state of the art, and the machinery we have is specific to our industry. It all looks very impressive, but you would not want to see our electric bill.

I install and service annealing furnaces in factories and shops. This can be a very expensive piece of equipment, mainly because it can safely reach some pretty high temperatures and still be safe to work around.

As far as complexity (and cost) goes, the ones in the metal shops are nothing compared to the ones that make computer chips. Metal is pretty easy. Heat it up and you can play with it pretty much however you want, within reason. A casting furnace has to reach thousands of degrees inside, but the product it is heating is pretty resilient.

Post your comments